CARATTERISTICHE_TECNICHE: NOT FOUND

CORE COVER

Resistenza a picchi temp. 140 °C 300 °C

Tenacity 48,1 gr/den 25,7 gr/den

Coeff. di frictyion 0,06 0,10

Grip winch/stopper moderate good

Smoothness excellent optimum

Abrasion resistance optimum optimum

Specific weight 0,97 gr/cm3 1,25 gr/cm3

Res. to continuos work optimum optimum

Colors range wide wide

Resistenza a picchi temp. 140 °C 300 °C

Tenacity 48,1 gr/den 25,7 gr/den

Coeff. di frictyion 0,06 0,10

Grip winch/stopper moderate good

Smoothness excellent optimum

Abrasion resistance optimum optimum

Specific weight 0,97 gr/cm3 1,25 gr/cm3

Res. to continuos work optimum optimum

Colors range wide wide

UTILIZZO: NOT FOUND

- High load halyards

- Control line

- Control line

RICHIEDI_INFO: NOT FOUND

GAMMA_COLORI: NOT FOUND:

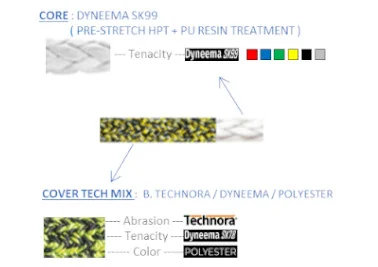

CORE DYNEEMA SK99 XTR-PU

The excellent creep qualities combined with a tenacity of 48,1 gr/den and a modulus of 1.801 gr/den make it possible to build an extremely resistant and reactive line, dedicated to maneuvers subjected to high dynamic loads.

Thanks to the reduced specific weight of 0.974 gr/cm3 the rope is extremely light, while the protective treatment with a mix of polyurethane resins makes it water-repellent and highly resistant to wear.

The hot pre-stretch treatment called XTR takes the diameter/load ratio to the extreme by reducing the section and at the same time increasing the breaking load.

Le eccellenti doti di creep unite a una tenacità di 48,1 gr/den e ad un modulo di 1.801 gr/den permettono di costruire una cima estremamente resistente e reattiva , dedicata a manovre sottoposte ad elevati carichi dinamici .

Grazie al ridotto peso specifico di 0,974 gr/cm3 la cima risulta estremamente leggera , mentre il trattamento di protezione con mix di resine poliuretaniche la rende idrorepellente e altamente resistente all'usura .

Il trattamento di prestazione a caldo denominato XTR porta all' estremo il rapporto diametro/carico riducendo la sezione ed aumentando al tempo stesso il carico di rottura .

COVER BLACK TECHNORA / DYNEEMA / POLIESTERE

It is a technical cover dedicated to high loads, temperatures and frictions.

The resistance to abrasion and continuous work is excellent.

The Black Technora inserts increase the tolerance to peak temperatures up to 301°C, guaranteeing excellent resistance to winch friction when changing manoeuvres.

The Dyneema inserts reduce the friction coefficient to 0.10, increasing smoothness in the circuits.

The Dyneema inserts also bring the tenacity of the cover to 25.7 gr/den , guaranteeing high efficiency on winches and clutches .

The color range is wide thanks to the polyester components which allow the maneuvers to be easily recognisable.

The excellent creep qualities combined with a tenacity of 48,1 gr/den and a modulus of 1.801 gr/den make it possible to build an extremely resistant and reactive line, dedicated to maneuvers subjected to high dynamic loads.

Thanks to the reduced specific weight of 0.974 gr/cm3 the rope is extremely light, while the protective treatment with a mix of polyurethane resins makes it water-repellent and highly resistant to wear.

The hot pre-stretch treatment called XTR takes the diameter/load ratio to the extreme by reducing the section and at the same time increasing the breaking load.

Le eccellenti doti di creep unite a una tenacità di 48,1 gr/den e ad un modulo di 1.801 gr/den permettono di costruire una cima estremamente resistente e reattiva , dedicata a manovre sottoposte ad elevati carichi dinamici .

Grazie al ridotto peso specifico di 0,974 gr/cm3 la cima risulta estremamente leggera , mentre il trattamento di protezione con mix di resine poliuretaniche la rende idrorepellente e altamente resistente all'usura .

Il trattamento di prestazione a caldo denominato XTR porta all' estremo il rapporto diametro/carico riducendo la sezione ed aumentando al tempo stesso il carico di rottura .

COVER BLACK TECHNORA / DYNEEMA / POLIESTERE

It is a technical cover dedicated to high loads, temperatures and frictions.

The resistance to abrasion and continuous work is excellent.

The Black Technora inserts increase the tolerance to peak temperatures up to 301°C, guaranteeing excellent resistance to winch friction when changing manoeuvres.

The Dyneema inserts reduce the friction coefficient to 0.10, increasing smoothness in the circuits.

The Dyneema inserts also bring the tenacity of the cover to 25.7 gr/den , guaranteeing high efficiency on winches and clutches .

The color range is wide thanks to the polyester components which allow the maneuvers to be easily recognisable.